Nitrogen liquefaction plant provides sub-cooled liquid nitrogen from gaseous nitrogen feed gas for the many applications that use liquid nitrogen. Our Nitrogen Liquifiers are designed to provide you with liquid nitrogen from any clean and dry gaseous nitrogen source, typically from the overhead nitrogen stream from an air separation plant (ASU) that would otherwise be vented.

Whatever your application or industry, our nitrogen liquifiers have the versatility needed to adapt to your specific needs, such as liquefying an oxygen gas stream or simultaneous liquefaction of oxygen and nitrogen gas streams.

How Nitrogen liquefaction plant Works

The process begins with the intake of air from the atmosphere. Atmospheric air is compressed, purified, cooled, and separated. Cool the air to about -300°F (-185°C) and then, separate it into its elemental components in the form of liquid oxygen, argon, and nitrogen, relying on their different boiling points. The purification of the air is performed by a reliable rapid pressure swing adsorber (RPSA).

The air compressor is a reliable, air-cooled, oil-flooded rotary screw machine. The refrigeration for liquefaction is provided by PCI’s highly reliable PLS turboexpander. And the bearing system has a self-contained internal passive lubrication system (PLS). The bearings are located outside the cold section of the system and operate at ambient temperatures.

The oil is fed to the bearings by capillary action on wicks. As a result, the lubrication system requires no pumps, filters, valves, etc. And this provides for a very simple and highly reliable refrigeration system.

Once into production, the plant is fully automatic. Generate cryogenic product (LIN or LOX) to the proper levels and automatically transfer it to a receiver. Thoroughly test all plants before shipping.

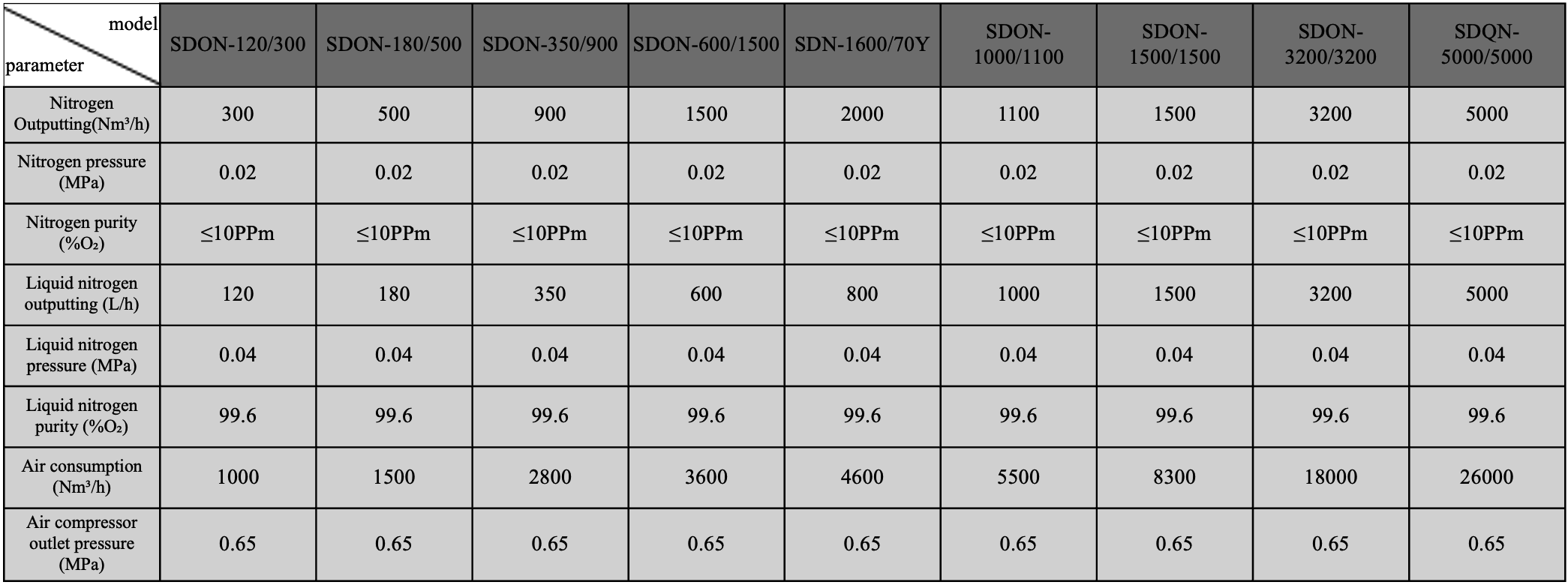

Technical parameters of small and medium cryogenic air separation equipment

Note: The data listed in this table are based on 0.8Mpa (gauge pressure) raw air, 20℃ambient temperature, 0m elevation and 80% relative humidity as the design basis.

Note: The data provided in this catalog is for reference only. The company reserves the right to change the product design at its own discretion. The detailed information is subject to the design drawings provided. For details, please contact the sales department of our company.

Our Standards and Options:

Design Sheng’er cryogenic air separation plants and liquefier units for minimal operator supervision. And the plants include automated process optimization, remote monitoring and control capabilities, provisions for automatic call-out of support personnel when out of range conditions are encountered, automatic shutdown if potentially unsafe conditions are detected. And automatic activation of backup liquid vaporization systems to maintain continuity of pipeline product deliveries.

Sheng’er cryogenic air separation plants and cryogenic oxygen plants utilize energy efficient dual column technology.

Sheng’er cryogenic nitrogen plants may employ single-column technology to produce nitrogen gas at common distribution pressures without a product compressor.

Cryogenic air separation cycles that pump LOX allow for the production of oxygen at pipeline distribution pressure, eliminating the need for an oxygen compressor.