Nitrogen generator

The pressure swing adsorption nitrogen production system uses carbon molecular sieves as adsorbents and operates on the principle of pressure swing adsorption to generate nitrogen gas.

production

Up to 5000Nm3/h

Warranty

24 months

Nitrogen purity

97%~99.9999%

Service life

20 years

Compressed Air Cylinder

The components used for compressing the molecular sieve ensure efficient and stable nitrogen production.

Pressure gauge

pressure gauge is an instrument used to measure and monitor pressure in gases or liquids. It serves the purpose of pressure monitoring, fault detection, safety control, and process monitoring and control in various industrial, manufacturing, and scientific applications.

pneumatic valve

The pneumatic valve is device that uses compressed air to control the flow of gases or fluids in a system. It operates by opening or closing to regulate the passage of the media, making it a key component in various industrial and automation processes.

pressure regulating valve

A pressure regulating valve is a device that controls and reduces fluid or gas pressure to a desired level in industrial systems.

Electromagnetic valve

an electromagnetic coil to open or close the valve. It finds applications in plumbing, heating, cooling, and automation systems.

alarm device

control box

Experts from Shenger will design a nitrogen station according to the individual requirements of the customer. All Shenger generators are manufactured in their own factory using the highest quality components to ensure maximum efficiency of the entire station. Shenger’s engineers will be responsible for commissioning and maintaining the site.

About Our Nitrogen Generators

Advanced control system

Rapid production of nitrogen

Gas quality is stable

Adsorbent has long service life

High efficiency production

Accelerate regeneration

Add Your Heading Text Here

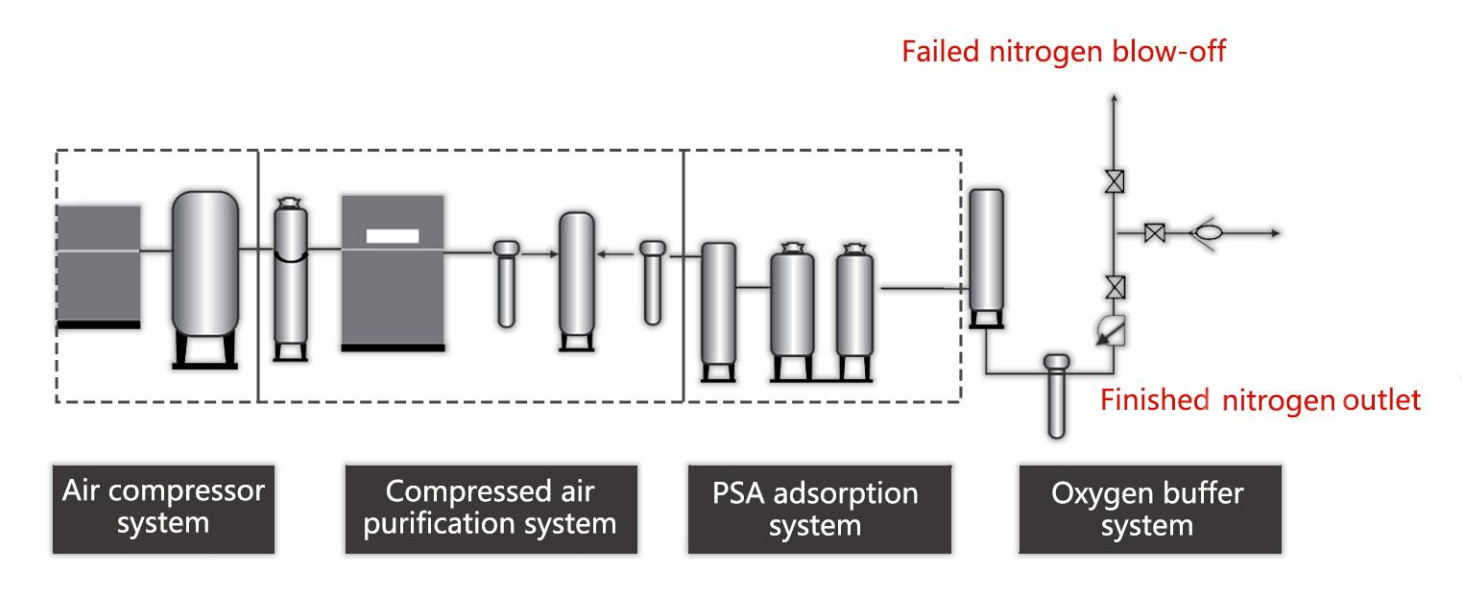

PSA nitrogen production system

It is primarily composed of an air compressor and an air buffer tank. The compressed air provided by the air compressor is first directed into the compressed air purification system. The purpose of the air tank system is to ensure a steady supply of air to the oxygen-nitrogen separation system and prevent excessively rapid airflow during transitions in the oxygen-nitrogen separation system, which could affect the efficiency of air purification. This, in turn, enhances the quality of compressed air entering the adsorber and extends the lifespan of the molecular sieve.

The compressed air purification system consists of a high-efficiency oil remover, a refrigerated air dryer, an activated carbon filter, and a precision filter. Compressed air passes through the mentioned equipment to remove oil, water, and dust and undergoes deep purification by the subsequent precision filter.

The PSA (Pressure Swing Adsorption) adsorption system consists of an air process tank, adsorption towers, pneumatic valves, a PLC controller, and compression devices, among other components. The adsorption system is the core part of the nitrogen generation unit, with its main components being two adsorption towers filled with carbon molecular sieves. When clean compressed air enters one of the adsorption towers, O2, CO2, and trace amounts of H2O are adsorbed by the carbon molecular sieve, while nitrogen is output from the exit as the product nitrogen gas.

When one tower is in the adsorption phase, the other tower undergoes depressurization to release the adsorbed O2, CO2, and H2O from the molecular sieve’s micropores, achieving the regeneration and desorption of the molecular sieve. The two towers alternate between adsorption and regeneration phases, ensuring a continuous output of nitrogen gas.

The unadsorbed nitrogen gas passes through the adsorption bed and flows into the nitrogen storage tank via the left inlet valve and the nitrogen generation valve. Once the left adsorption process is completed, adsorption towers A and B are connected through upper and lower pressure balance valves to equalize the pressure in both A and B adsorption towers.

This process is referred to as pressure equalization. After pressure equalization, compressed air enters adsorption tower B through the right inlet valve, and oxygen molecules in the compressed air are adsorbed by the carbon molecular sieve. The concentrated nitrogen gas then flows into the nitrogen storage tank through the right inlet valve and the nitrogen generation valve.