In the industrial sector, combination air dryer plays a crucial role in ensuring production efficiency and product quality.

The combination air dryer ingeniously integrates the features of a refrigerated dryer and a micro-heat regeneration dryer through a patented new process. This low-energy, energy-efficient product is designed to meet high-quality requirements for gas dew points. It encompasses all the advantages of both a refrigerated dryer and a micro-heat adsorption dryer.

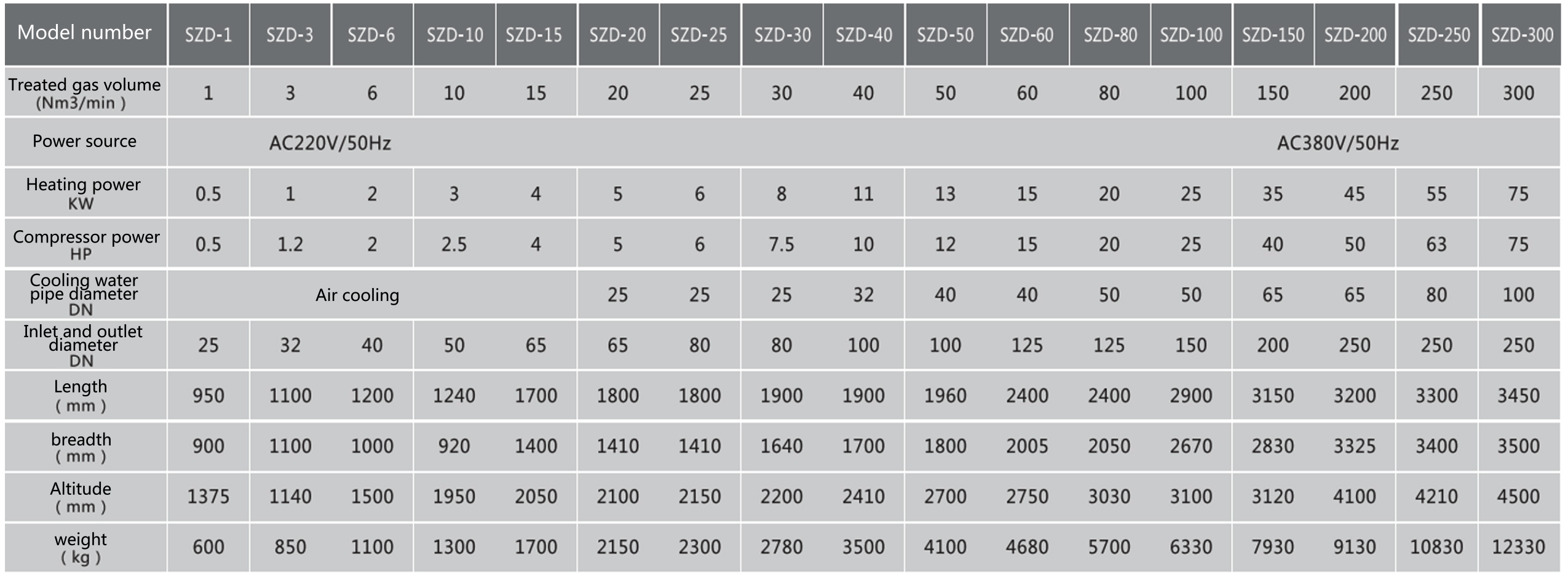

Technical Parameters

Working pressure:0.6~1.0 MPa (can be provided at 1.0~3.0 MPa according to user requirements)

Pressure Drop: ≤0.045 MPa

Inlet Temperature: ≤ 45°C

Regeneration Gas Consumption: < 1~3%

Cooling Method: Water cooling or Air cooling

Final Product Dew Point at Atmospheric Pressure: -40°C – 70°C

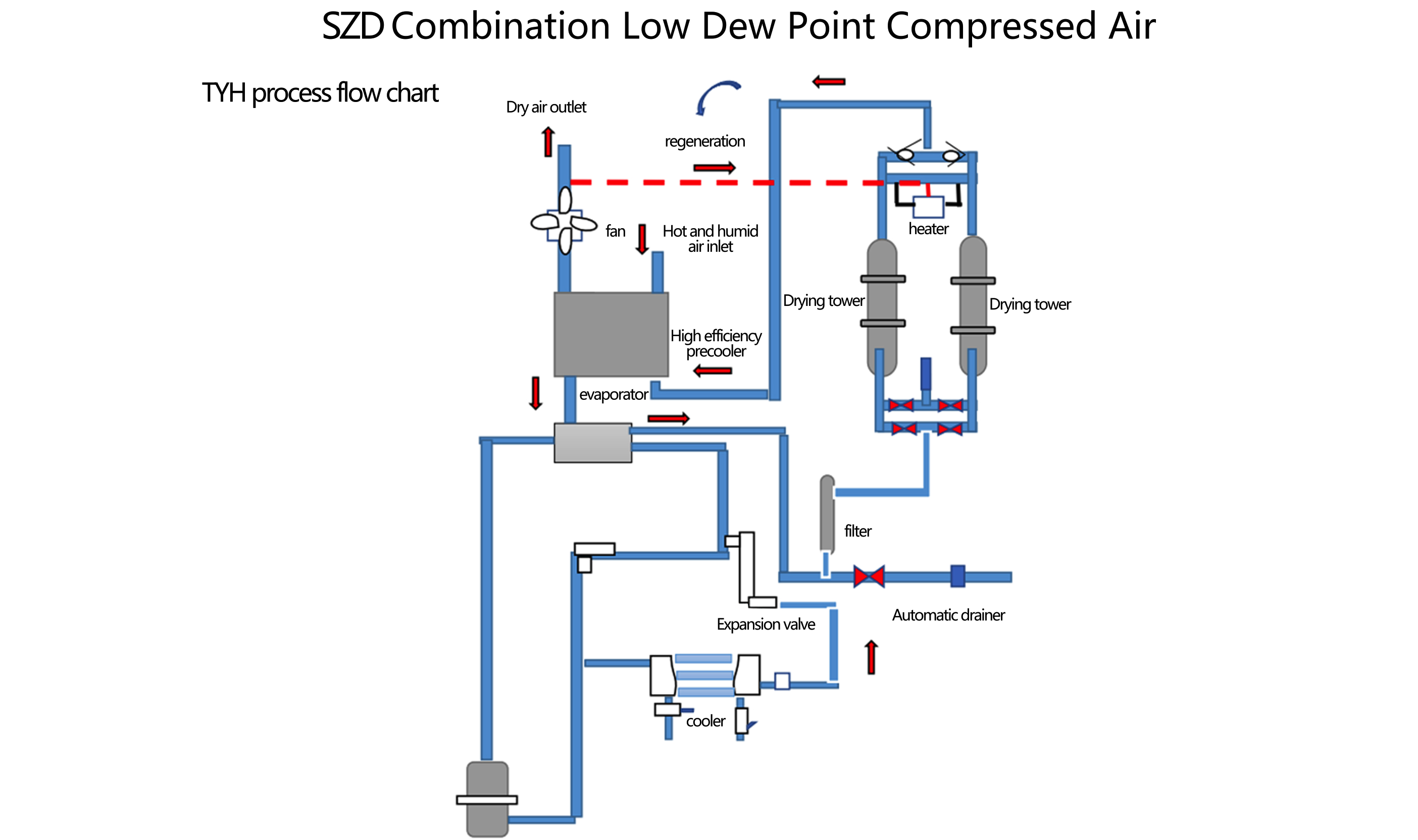

Combination Air Dryer Process Drawing

The compressed air enters the combination dryer, and due to the temperature increase during gas compresion, it initially undergoes temperaturereduction in the high-efficiency pre-cooler. it then enters the evaporator, further lowering the temperature to around 2’c. At this pressure dewpoint most gaseous moisture turns into liquid water and is automatically discharged by the drain,followed by additional moisture removal througla filter. The air then enters the drying tower for further drying and dehumidification, resulting in a final product with an even lower dew point Thedry compressed air, after cooling, re-enters the hicgh-eficiency pre-cooler, where it cools the high-temperature, high-humidity air. imultaneouslvits temperature increases, preventing condensation on the outer surface of transport pipes. A small portion ofthe warmed compressed air is used

The compressed air enters the combination dryer, and due to the temperature increase during gas compresion, it initially undergoes temperaturereduction in the high-efficiency pre-cooler. it then enters the evaporator, further lowering the temperature to around 2’c. At this pressure dewpoint most gaseous moisture turns into liquid water and is automatically discharged by the drain,followed by additional moisture removal througla filter. The air then enters the drying tower for further drying and dehumidification, resulting in a final product with an even lower dew point Thedry compressed air, after cooling, re-enters the hicgh-eficiency pre-cooler, where it cools the high-temperature, high-humidity air. imultaneouslvits temperature increases, preventing condensation on the outer surface of transport pipes. A small portion ofthe warmed compressed air is used

for adsorbent regeneration, enhancing regeneration efficiency and reducing energy consumption.

Technical Parameters

Technical Advantages of combination air dryer

The Combination Dryer offers significant technical advantages compared to traditional models. Its low-pressure design reduces energy consumption, enhancing energy efficiency. Additionally, an advanced control system ensures stable operation and allows intelligent adjustments based on actual needs, minimizing energy wastage. The application of this advanced technology not only extends the equipment’s lifespan but also improves production efficiency.

Application Industries of combination air dryer

The Combination Dryer finds widespread application in pharmaceuticals, food processing, electronics manufacturing, and other industries.

- In the pharmaceutical sector, it ensures that the drying air meets clean standards, guaranteeing the quality of pharmaceutical products.

- During food processing, the equipment prevents moisture-related spoilage, maintaining the taste and quality of products.

- For electronics manufacturing, the low-pressure dew point dryer helps prevent damage to electronic devices caused by humidity, ensuring product reliability.

So, the Combination Air Dryer stands as a cornerstone in the air treatment field, offering reliable humidity control solutions with its exceptional working principle, advanced technical advantages, and wide-ranging applications across various industries.