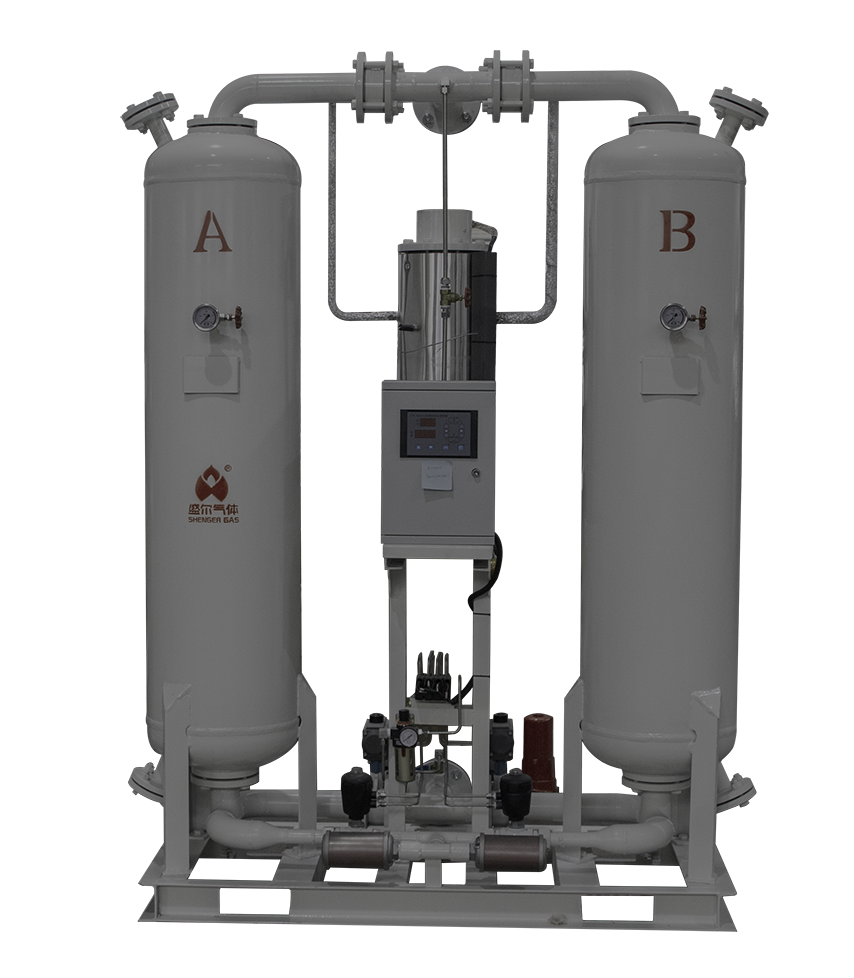

Micro Heat Regeneration Adsorption Dryer, a breakthrough in moisture removal technology, offers unparalleled efficiency in various industrial applications. This article delves into the working principle, technical features, and conventional technical parameters of this innovative dryer.

Working Principle of Micro heat regeneration dryer:

The dehumidification principle of the micro heat regeneration adsorption dryer is essentially the same as the heatless regeneration type. The key difference is that low-pressure drying air, used for regeneration, first undergoes a return process before entering the regeneration tower to dehydrate the desiccant.

This design adds a heating device in the structure and incorporates return and cool blow procedures in the regeneration process. The micro heat regeneration adsorption dryer offers advantages such as minimal energy wastage, only 6%, and exhibits longer switching cycles, reduced mechanical wear, enhancing equipment reliability. Ultimately, it achieves a better dew point for the final product gas compared to the heatless regeneration type.

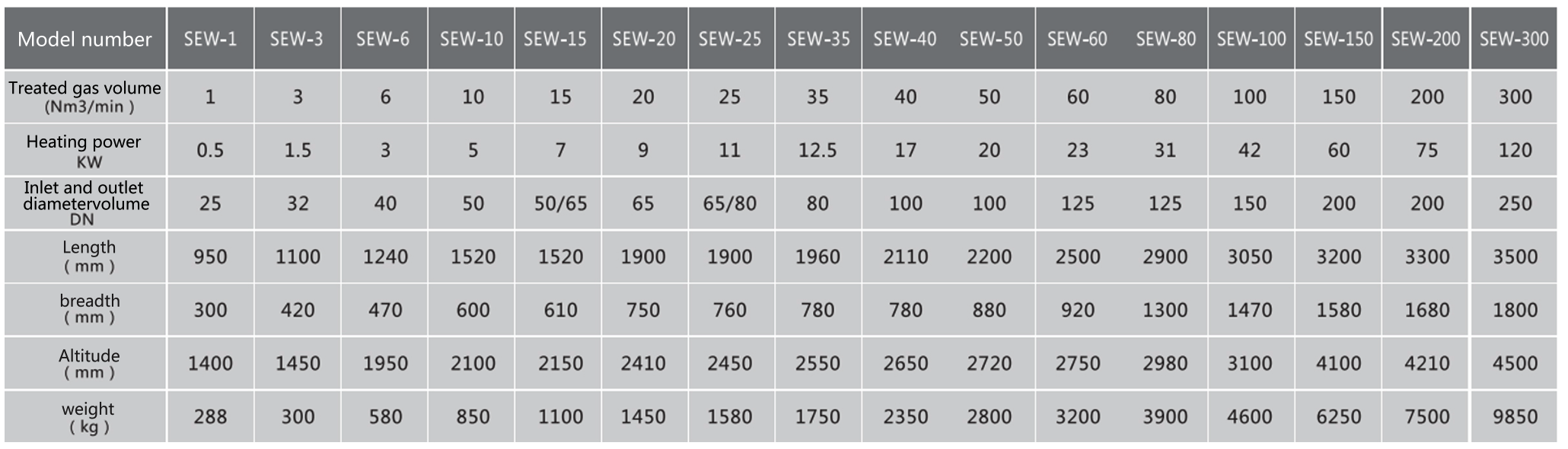

Technical Parameters:

Technical Parameters

Working pressure:0.6~1.0 MPa (can be provided at 1.0~3.0 MPa according to user requirements)

Working pressure:0.6~1.0 MPa (can be provided at 1.0~3.0 MPa according to user requirements)

Final Product Dew Point at Atmospheric Pressure: -40°C (alumina) -60°C (molecular sieve)

Pressure Drop: ≤0.023 MPa

Inlet Temperature: ≤ 45°C

Regeneration Gas Consumption: < 4%~6%

Regeneration Method: Heatless Regeneration

Operating Mode: Two adsorption towers operate alternately and continuously

Control Mode: Automatic Control

Technical Features of Micro heat regeneration dryer :

- It simultaneously combines the advantages of both thermal and heatless regeneration;

- Adopting a micro-heating approach for the regeneration air to reduce energy consumption, achieving energy efficiency goals;

- This design mitigates the drawbacks of short switching times and high regeneration air loss in heatless regeneration dryers, while also avoiding the substantial energy consumption associated with heated regeneration air dryers;

- With reasonable switching times and minimal regeneration air consumption.

It stands as a cost-effective and energy-efficient adsorption dryer in the purification industry. Widely applied in industries such as metallurgy, power, electronics, food, chemical, and petroleum.

The Micro Heat Adsorption Air Dryer boasts several key technical features that set it a part from conventional drying solutions. Firstly, its compact design makes it suitable for space-constrained environments. Additionally, the micro heat regeneration technology enhances energy efficiency, reducing operational costs. The dryer also incorporates intelligent controls for precise moisture removal, adapting to varying humidity levels.