pressure drop represents the decrease in fluid pressure from one point of a system to another. This phenomenon is pivotal in engineering, dictating the design and efficiency of fluid transport systems. This article aims to dissect the nuances of pressure, exploring its calculation, implications, and strategies for mitigation.

What Means Pressure Drop?

Pressure drop is the reduction in pressure experienced by a fluid as it moves through a conduit or system. This occurs due to friction between the fluid and the conduit walls, as well as any obstacles it encounters, such as valves, bends, and fittings. Understanding this concept is fundamental in engineering applications, where fluid dynamics play a critical role.

Pressure Drop Formula

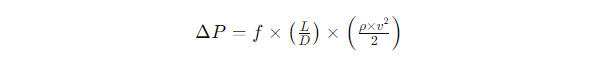

The Darcy-Weisbach equation stands as the cornerstone for calculating pressure drop in incompressible flows through pipes:

- ΔP: pressure drop;

- f: the friction factor;

- L: length of the pipe;

- D: the diameter of the pipe;

- ρ: the density of the fluid;

- v: the velocity of the fluid.

For gases, the equation adjusts to accommodate compressibility and temperature variations, adding layers of complexity.

How Do You Calculate Pressure Drop?

Calculating necessitates a comprehensive understanding of the fluid properties (density, viscosity) and system characteristics (pipe length, diameter, roughness, and flow rate). The process involves:

- Determining the flow regime (laminar or turbulent) using the Reynolds number.

- Calculating the friction factor, which varies with flow regime and pipe roughness.

- Applying the Darcy-Weisbach equation or empirical formulas tailored to specific conditions, such as the Hazen-Williams equation for water flow in pipes.

Software tools offer streamlined calculations, incorporating complex variables and providing accurate predictions.

What Is the Effect

In practice, demands more energy from pumps and compressors to maintain flow rates, directly influencing operational costs and system efficiency. In air separation units, for instance, minimizing pressure drop is crucial for maximizing yield and reducing energy consumption. Conversely, a meticulously managed pressure drop can enhance system performance, prolong equipment lifespan, and optimize energy use.

In industrial settings, the consequences of ignoring pressure drop can be profound. Systems may face increased wear and tear, leading to more frequent shutdowns and maintenance. For sensitive processes, like chemical reactions or precision manufacturing, fluctuations in pressure drop can affect product quality and consistency.

Strategies for Mitigating

Mitigation starts with design – choosing wider pipes, reducing unnecessary bends, and selecting low-resistance fittings. Regular maintenance, such as cleaning filters and inspecting for obstructions, ensures optimal flow conditions. Advanced materials and coatings can also reduce internal friction, offering long-term benefits.

Conclusion

Understanding and managing pressure drop is not just an academic exercise but a practical necessity. It influences design decisions, operational costs, and system efficiency. With the right knowledge and tools, engineers can predict, calculate, and mitigate, leading to more energy-efficient and cost-effective fluid transport systems.