In the realm of laser cutter, the choice of assist gas plays a pivotal role in determining the quality, speed, and cost-effectiveness of the cutting process. Among the contenders, nitrogen stands out as a premier choice for a variety of reasons. This article delves into the nuances of using nitrogen in laser cutting, exploring why it’s considered the best gas for the job, its specific uses, and the requisite pressure for optimal cutting performance.

Which Gas is Best for Laser Cutting?

When it comes to laser cutting, the assist gas used can make a significant difference in the outcome. Oxygen, air, and nitrogen are the most commonly used gases, each with its own set of advantages. However, nitrogen is often hailed as the best choice, especially for metals like stainless steel, aluminum, and carbon steel. The reason? Nitrogen cutting produces edges that are cleaner, sharper, and free from oxidation. This means no additional finishing is required, making it a cut above the rest.

Why Use Nitrogen for Laser Cutting?

Nitrogen’s popularity in laser cutting isn’t just hot air. This inert gas brings several benefits to the cutting process. Firstly, it prevents oxidation by displacing oxygen from the cutting zone, ensuring clean and smooth edges. This is particularly crucial for materials that are prone to discoloration or weakening due to heat. Furthermore, nitrogen cutting minimizes the risk of warping, making it ideal for precision applications. It’s like having a meticulous artist at work, except it’s a gas doing the precision job.

What is the Use of Nitrogen in Laser Cutting?

The role of nitrogen in laser cutting is multifaceted. Beyond ensuring clean cuts, it aids in the ejection of molten material from the kerf, the narrow slit made by the laser. This ensures the laser beam can continue its path unobstructed, resulting in more accurate and efficient cuts. Nitrogen also helps in reducing the thermal impact on the material being cut, preserving its mechanical properties. In essence, nitrogen is the silent guardian of quality and precision in laser cutting operations.

What Pressure is Needed for Nitrogen Laser Cutting?

The pressure of nitrogen required for laser cutting can vary depending on the thickness of the material and the type of laser cutter used. Typically, pressures range from 6 to 25 bar (87 to 362 psi). Thicker materials generally require higher pressures to effectively blow molten material out of the kerf. It’s a bit like finding the perfect water pressure for your garden hose; too little and you won’t get all the leaves off your path, too much and you might end up blasting your flowers away. Similarly, getting the pressure right in nitrogen laser cutting is key to achieving optimal results.

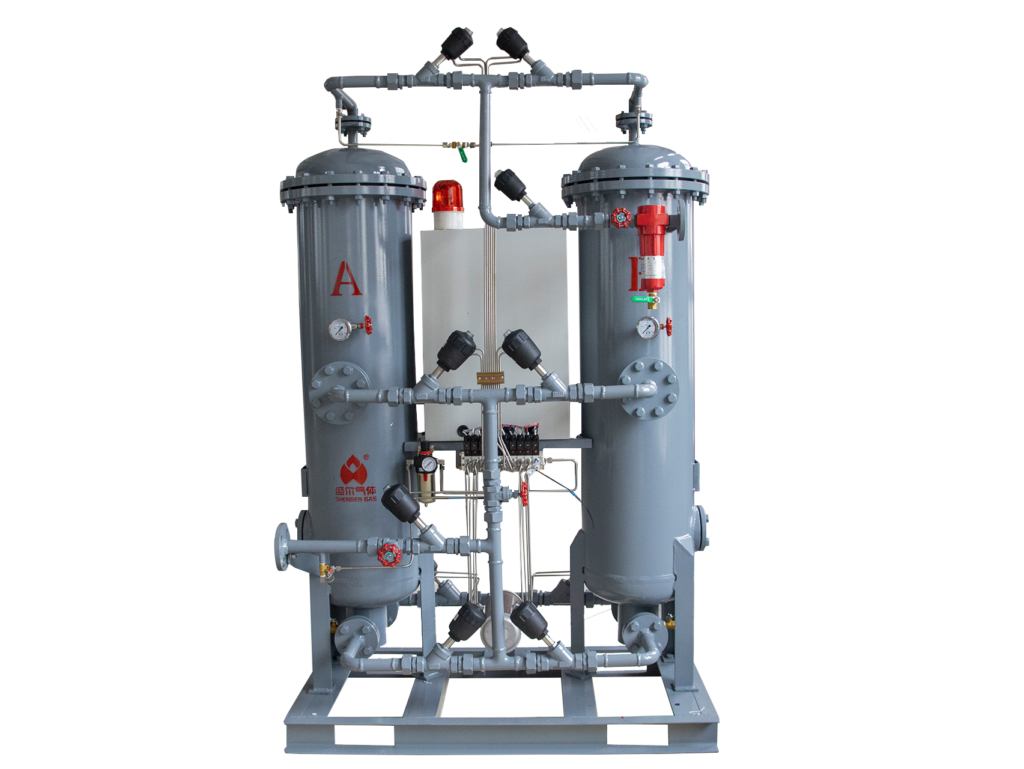

The use of a nitrogen generator for laser cutting is akin to having a secret weapon in your manufacturing arsenal. It enhances the quality, efficiency, and aesthetics of the cuts, making it an invaluable tool in the industry. Just like a chef relies on the best ingredients for a perfect dish, so does a laser cutter on high-quality nitrogen for impeccable cuts. Remember, in the world of laser cutting, nitrogen isn’t just another gas; it’s the breath of quality and precision.