The separation of nitrogen from air is a critical process in various industrial applications, including the production of high-purity gases for electronics manufacturing, the food industry, and the creation of inert atmospheres for chemical processes. This article delves into three primary methods used for nitrogen separation: cryogenic distillation, pressure swing adsorption (PSA), and membrane nitrogen generation.

Cryogenic Distillation

Cryogenic distillation is the most established and widely used method for air separation, capable of producing nitrogen with very high purity levels, often above 99.999%. The process begins with the purification and cooling of air to extremely low temperatures, below -196°C, at which point air becomes a liquid.

This liquefied air is then introduced into a distillation column, where it is gradually warmed up. Since the various components of air have different boiling points, they can be separated as they vaporize at different temperatures.

Oxygen, having a higher boiling point than nitrogen, remains liquid longer and is collected at the bottom of the column, while nitrogen gas, which vaporizes first, is collected at the top.Cryogenic distillation is highly efficient for large-scale production but requires substantial energy input and significant infrastructure investment, making it less suitable for small-scale applications.

Pressure Swing Adsorption (PSA)

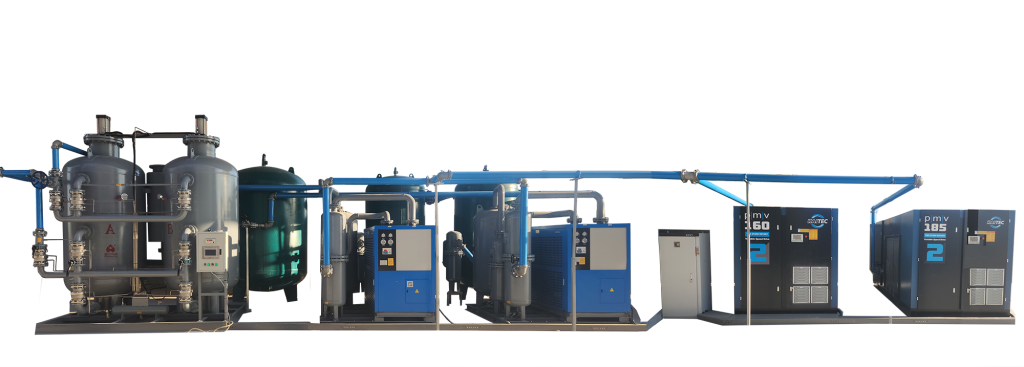

Pressure swing adsorption is a versatile and energy-efficient method for nitrogen production, particularly favored for its adaptability to various purity requirements and scales of operation. The PSA process relies on the ability of specific materials, known as adsorbents, to preferentially adsorb oxygen. Common adsorbents include zeolites and activated carbon, which have large surface areas and are capable of selectively adsorbing oxygen molecules.

In PSA unit, compressed air is passed through a vessel containing the adsorbent material. Oxygen is trapped in the pores of the adsorbent, while nitrogen passes through and is collected as the product gas. Once the adsorbent is saturated with oxygen, the pressure is rapidly reduced, releasing the adsorbed oxygen, which is then vented.

PSA systems can achieve nitrogen purities up to 99.999%, with the advantage of lower energy consumption compared to cryogenic distillation. However, the purity and flow rate can be limited by the characteristics of the adsorbent material and the design of the system.

Membrane Nitrogen Generation

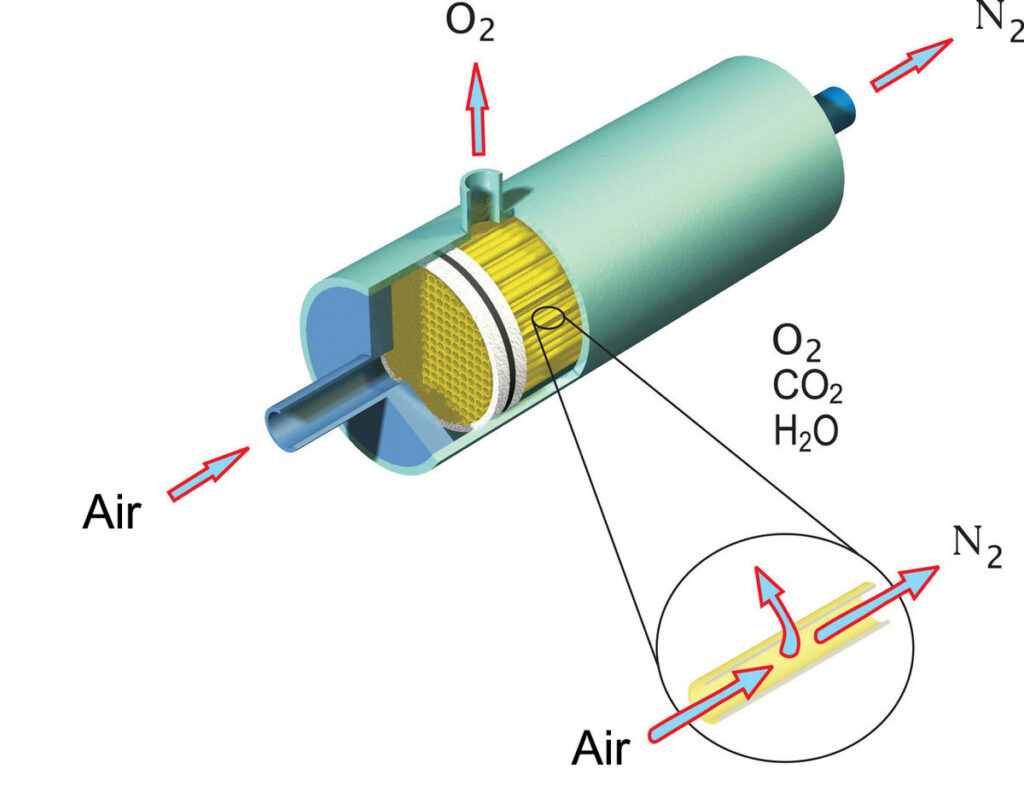

Membrane nitrogen generation suitable for applications requiring moderate purity levels, typically ranging from 95% to 99.5%. This method utilizes semi-permeable membranes composed of polymers that facilitate the differential diffusion of gases. When compressed air is passed over the membrane, oxygen, carbon dioxide, and water vapor diffuse through the membrane faster than nitrogen, thereby enriching the gas stream on the other side with nitrogen.

The purity of nitrogen produced by membrane systems can be adjusted by changing the flow rate of air through the membrane or by altering the operating pressure. Membrane nitrogen generators are particularly valued for their simplicity, low maintenance, and ease of operation, making them ideal for small to medium-scale applications where extremely high purity levels are not necessary.

Each of these nitrogen separation methods offers distinct advantages and limitations, making them suitable for different industrial applications based on the required purity, scale, and economic considerations. Understanding the principles and operational characteristics of cryogenic distillation, pressure swing adsorption, and membrane nitrogen generation is essential for selecting the most appropriate technology for specific nitrogen production needs.