In various industrial applications, nitrogen purity is a critical parameter. When the Low Nitrogen Purity in Nitrogen Generators, it can have serious implications for the production process and the quality of the end product. Understanding the reasons behind the decline in nitrogen purity, how to address the issue, and how to maintain and care for the generator is essential. This article delves into these three areas.

Causes for Low Nitrogen Purity in Nitrogen Generators

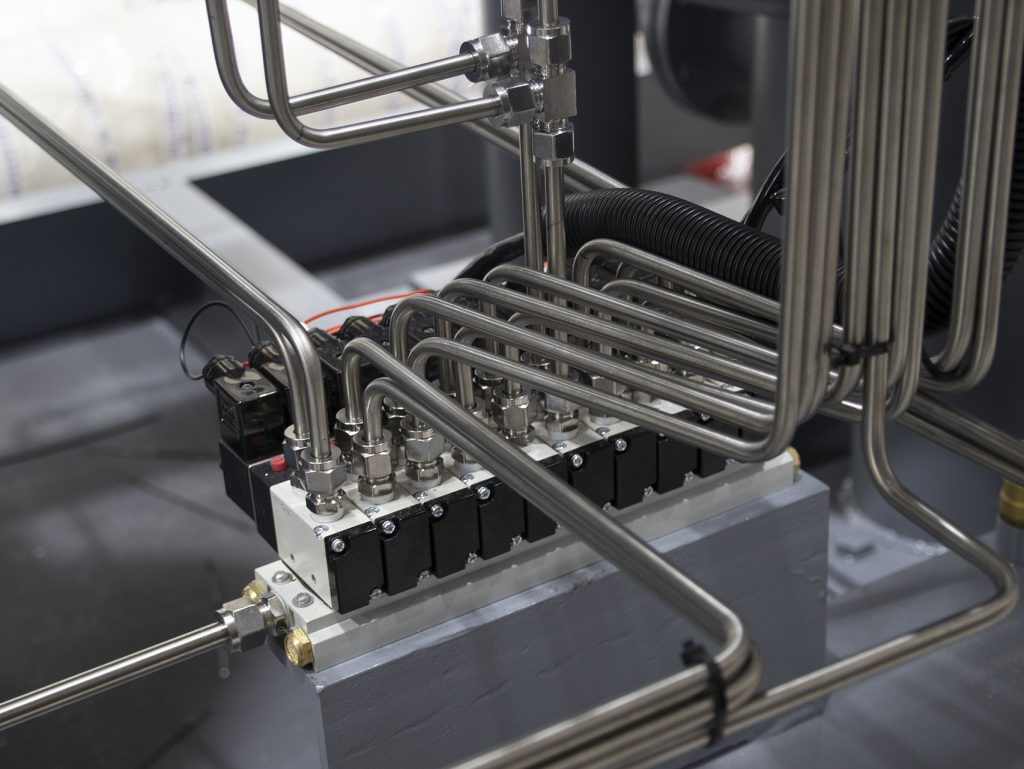

Filter Issues: Filters are one of the essential components of a nitrogen generator. When filters get clogged or age, they might allow oxygen and other impurities to seep in, reducing the purity of the nitrogen.

Aging or Damaged Molecular Sieves: Molecular sieves, the primary materials in nitrogen generators used for separating nitrogen from oxygen, can age or get damaged over time, leading to reduced separation efficiency.

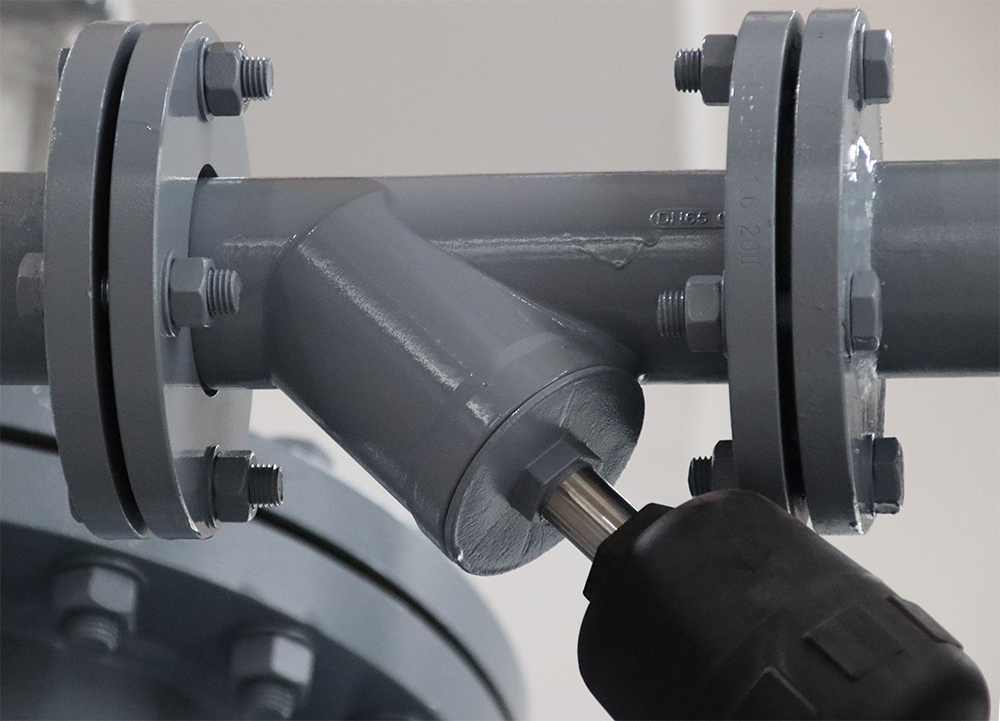

Equipment Leakage: Any minor leak in the machine might allow external gases to infiltrate, compromising the nitrogen’s purity.

Environmental Issues: Factors like high temperatures, high humidity, and polluted environments can adversely affect nitrogen purity.

Solutions for Low Nitrogen Purity

Replace or Clean Filters: Regularly inspect and replace or clean blocked or aged filters to ensure they are always in optimal condition.

Replace Molecular Sieves: When molecular sieves age or get damaged, it’s imperative to replace them with new ones promptly.

Inspect and Repair Equipment Leakage: Frequently check the nitrogen generator to ensure all connections are tight and there’s no leakage.

Adjust Operating Environment: Ensure the nitrogen generator operates at appropriate temperatures and humidity levels and try to avoid polluted environments.

Maintenance and Care for Nitrogen Generators

Regular Inspection: Periodically conduct a comprehensive check of the nitrogen generator to ensure all its components are in good condition.

Cleaning and Lubrication: Ensure all moving parts of the generator are adequately lubricated to minimize wear and tear. Additionally, clean the machine regularly to prevent the accumulation of dust and impurities.

Avoid Overuse: Although many nitrogen generators are designed to be robust, continuous operation might lead to premature wear. It’s recommended to allow breaks and cooling periods.

Train Operators: Ensure that individuals operating the nitrogen generator have received adequate training on its proper and safe use, and how to identify and address potential issues.

In conclusion, the purity of nitrogen from nitrogen generators is of paramount importance for many industrial applications. Recognizing and addressing potential issues, coupled with regular maintenance and care of the machine, is key to ensuring its efficient and consistent operation.