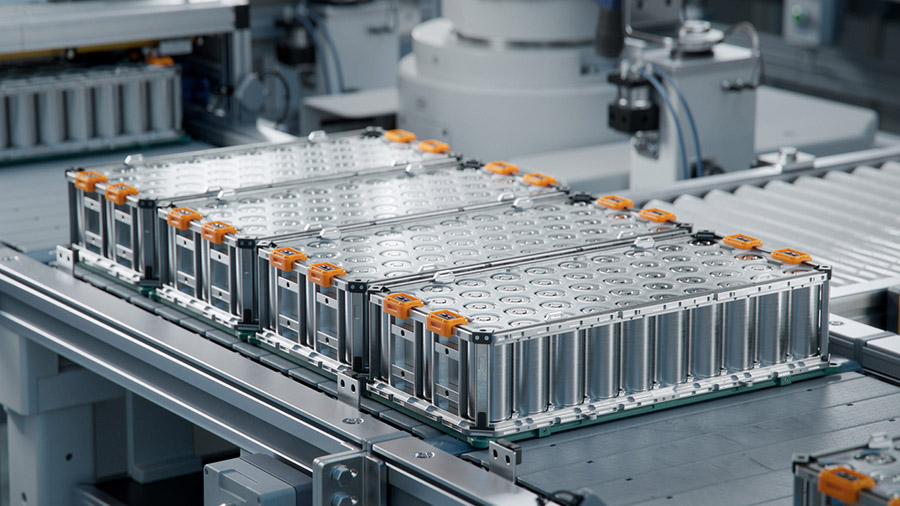

As the rise of electric vehicles and renewable energy continues, lithium batteries have become increasingly vital as advanced energy storage solutions. In the critical stages of lithium battery manufacturing, Air Separation Units play an indispensable role by providing high-purity gases. This article delves into the applications of ASUs in the lithium battery industry, focusing on the pivotal roles of oxygen in the preparation of ternary materials and nitrogen in the manufacturing of lithium iron phosphate batteries.

The Criticality of Oxygen in Ternary Material Preparation

Oxygen plays a crucial role in the preparation of ternary materials (such as nickel cobalt aluminum or nickel cobalt manganese). ASUs, by supplying high-purity oxygen, ensure the materials’ preparation occurs within a precisely controlled oxygen environment. This is paramount for the consistency and performance of the battery’s positive electrode materials, thus influencing the overall battery’s reliability.

Oxygen Demand in the Reaction of Nickel Cobalt Aluminum

In the positive electrode materials of batteries, such as nickel cobalt aluminum (NCA) or nickel cobalt manganese (NCM) oxides, the synthesis requires specific oxygen concentrations. High-quality oxygen supplied by ASUs makes the production process more precise and efficient, ensuring stable and reliable battery performance.

Application of Nitrogen in the Manufacturing

In the manufacturing of lithium iron phosphate batteries, the calcination furnace is a crucial step used for sintering positive electrode materials. To prevent materials from reacting adversely with the oxygen in the air at high temperatures, high-purity nitrogen is used as a protective gas. This ensures the quality of positive electrode materials and shields battery performance from the influence of oxygen.

Key Measures for Prolonging Battery Life

The application of ASUs not only ensures the excellent preparation of battery materials but also plays a positive role in other critical steps of battery manufacturing. The use of nitrogen not only provides effective oxygen protection in the calcination furnace but also plays a crucial role in cooling and refrigeration processes, enhancing battery life and performance consistency.

The application of ASUs in the lithium battery industry not only guarantees high-quality production but also serves as an indispensable tool for improving production efficiency. By ensuring the high-quality supply of oxygen and nitrogen, manufacturers can stand out in the competitive market. Choosing reliable air separation solutions will bring higher efficiency and more sustainable development to lithium battery manufacturers.

Understanding the crucial role of ASUs in the lithium battery industry allows manufacturers to optimize their production processes, enhance product quality, and gain a competitive edge in the market. In the future, as technology continues to advance, air separation technology will continue to play an increasingly important role in the lithium battery industry.