The management of dew point in compressed air systems is not just a matter of operational efficiency—it’s a critical component in preventing equipment degradation and ensuring product quality. This article delves deeper into the nuances of dew point, providing data-backed insights to underline its importance and guide on its optimization.

What is the Dew Point in Compressed Air?

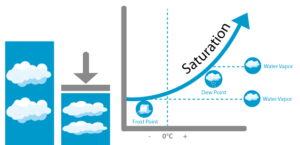

The dew point signifies the temperature at which air’s moisture content condenses into water. In compressed air systems, maintaining a dew point below certain temperatures is crucial. For instance, a typical recommended dew point for general industrial applications might be -40°C (-40°F), which ensures that moisture will not condense under any operating condition within the system.

Atmospheric Dew Point vs. Pressure Dew Point

The distinction between atmospheric and pressure dew point is vital. While the atmospheric dew point is relevant at 101.3 kPa (1 atm), compressed air systems operate at higher pressures, where the dew point behaves differently. For example, air compressed to 7 bars and cooled to 25°C without drying might reach a pressure dew point of +10°C, risking water formation in pipelines and equipment.

The Impact of Pressure on Dew Point

The relationship between pressure and dew point is governed by physics. As pressure increases in a compressed air system, the ability of air to hold moisture changes, thus affecting the dew point. Data shows that if compressed air at 100 psi is cooled to 20°C without moisture removal, its relative humidity could soar above 100%, leading to condensation.

It is easier for liquid water to enter the compressed air system at this point because the gas can easily reach its saturation point. This is why air dryersare so commonly used with compressed air systems.

Why Dew Point is Important for Compressed Air Systems

The significance of dew point control extends beyond preventing moisture condensation. For precision applications, such as in pharmaceuticals or electronics manufacturing, maintaining a dew point of -60°C (-76°F) can be critical to avoid product contamination. Data indicates that every 6°C decrease in dew point can significantly reduce the risk of moisture-related defects in sensitive manufacturing processes.

How to Lower the Dew Point in Compressed Air

Techniques for dew point reduction include:

- Refrigerated Dryers: Capable of achieving dew points as low as +3°C (+37°F), suitable for general industrial applications.

- Desiccant Dryers: These can lower dew points to -40°C (-40°F) or even -70°C (-94°F), essential for more sensitive applications. Efficiency varies, with some models achieving moisture removal efficiencies of up to 99%.

Measuring Dew Point

Accurate dew point measurement is achievable through technologies like:

- Chilled Mirror Hygrometers: Offering precision up to ±0.2°C, but more suited for laboratory settings.

- Capacitance Sensors: Used in industrial environments, with a general accuracy of ±2°C, suitable for a wide range of applications.

Effective dew point management in compressed air systems is crucial for operational efficiency, equipment durability, and product quality. Employing the right drying technologies and accurate dew point measurement tools allows industries to prevent moisture-related issues, ensuring reliable and cost-effective operations.