In the realm of air treatment and moisture control, regenerative desiccant air dryers stand out for their efficiency and reliability. These specialized systems play a crucial role in various industrial processes by providing dry air to prevent moisture-related issues. This article delves into the fundamentals of desiccant air dryers, their working principles, the types available, and the applications they serve.

What is a Desiccant Air Dryer?

A desiccant air dryer is a device used to remove water vapor from compressed air. It employs a desiccant material that adsorbs moisture from the air, ensuring that the downstream air is dry. These dryers are essential in preventing water from interfering with pneumatic systems, causing corrosion, or freezing in pipelines.

How do Regenerative Desiccant Air Dryers Work?

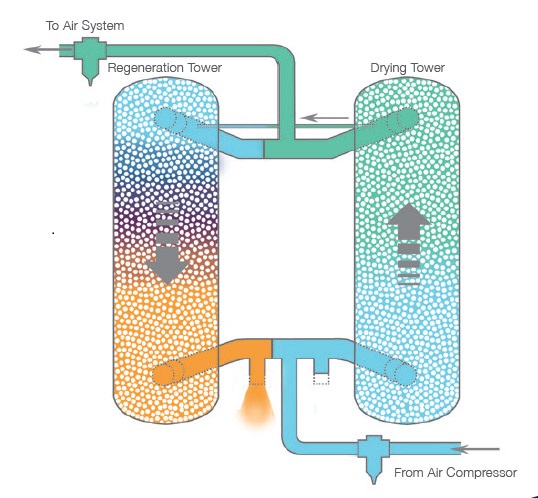

Regenerative desiccant air dryers utilize a dual-tower design, where one tower adsorbs moisture from the air while the other regenerates the desiccant material. The process involves several key steps:

- Adsorption Phase: Compressed air enters one of the towers, passing through the desiccant material. Moisture in the air is adsorbed, and dry air exits the system for use in operations.

- Regeneration Phase: Concurrently, the desiccant in the other tower is regenerated. This can be achieved through heatless (pressure swing) or heated regeneration methods, where the adsorbed moisture is removed from the desiccant, preparing it for another cycle of moisture adsorption.

- Switching: Once the adsorption phase is complete, the system switches operations. The regenerated tower begins drying the air, while the saturated tower undergoes regeneration.

Types of Desiccant Air Dryers

There are primarily two types of regenerative desiccant air dryers, differentiated by their regeneration methods:

- Heatless (Pressure Swing) Dryers: These utilize changes in pressure to regenerate the desiccant. A portion of the dried air is diverted back through the saturated desiccant bed, expanding and thereby reducing its moisture-holding capacity, which causes it to release the adsorbed water.

- Heated Dryers: These use an external heat source to warm the desiccant, accelerating the moisture release process. Heated dryers are more energy-efficient for larger systems, as they reduce the amount of compressed air needed for regeneration.

The Role of Desiccant in Air Dryers

The desiccant is the heart of the dryer, responsible for the moisture removal efficiency. Common desiccants include silica gel, activated alumina, and molecular sieves. Each has unique properties, such as pore size and adsorption capacity, making them suitable for different applications and dew point requirements(ScienceDirect).

Activated Alumina

- Description: Activated alumina is produced by dehydroxylating aluminium hydroxide in a way that produces a highly porous material. It has a high surface area which can adsorb significant amounts of water.

- Applications: Besides air drying, it’s used for fluoride removal from water, drying of sulfur recovery in refineries, and in the drying of organic liquids.

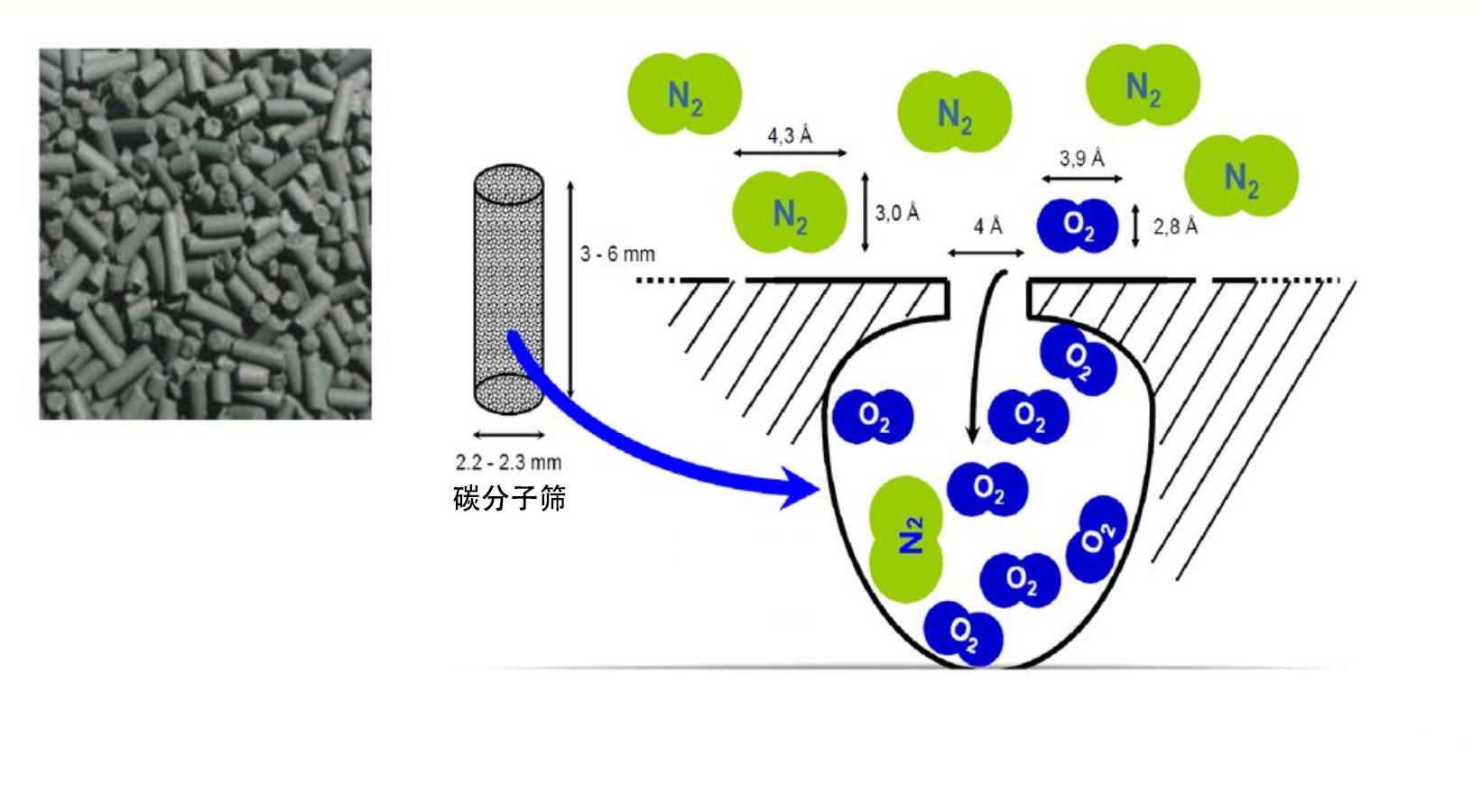

Molecular Sieves

- Description: Molecular sieves are synthetic zeolites with a uniform pore structure that enables selective adsorption of water molecules. They are highly effective at removing water vapor to achieve very low dew points.

- Applications: Employed in applications requiring very dry air or gases, such as the electronics industry, pharmaceutical manufacturing, and in the packaging of moisture-sensitive products. They are also used in the petrochemical industry for drying and purifying gases.

regenerative desiccant air dryers are critical components in maintaining the integrity and efficiency of industrial processes. Their ability to provide dry, moisture-free air helps industries meet stringent quality standards, protecting equipment and ensuring product quality. With the advancement in dryer technologies, selecting the appropriate type and maintenance practices can result in significant energy savings and operational efficiencies.